Standing seam for roofing

- Roofing

- Clips

- Hidden

- Standing

- Standing seam

- Fast and easy installation using traditional clips

- Maximum wind resistance

- Suitable for low to high hygrometry

- Traditional system widely used throughout the world

Overview

The standing seam system consists of a comprehensive range of robust components that ensures appropriate and correct installation is achieved. It is also important that standing seam roofs are installed by properly trained and equipped professionals.

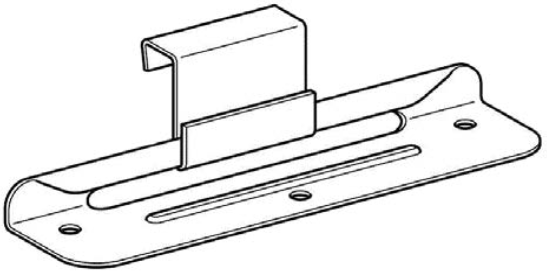

Individual panels are held in place at the top of the pitch by a minimum of 5 fixed clips and then towards the lower portion of the panel by sliding clips allowing thermal movement. These stainless steel clips, which are fixed to the structure, are crimped inside the joints. Thus the fixing clips for panels and flashings never penetrate the material and therefore do not affect the appearance or damage the waterproofing. The low height of the seams (25mm standard) and the 600mm maximum spacing between joints give the roof a light, harmonious appearance.

The standing seam system is available in various standard coil dimensions shown in the table on the opposite page. Non-standard widths between 60mm and 600mm can also be produced.

Areas of application

Minimum slope 15° (25%) - All types of buildings : commercial, public buildings, collective and individual housing.

Dimensions

| Length | 10000.0 mm |

|---|---|

| Thickness | 0.7 mm |

Finishes

See all aspects-

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Green

PIGMENTO Green -

PIGMENTO Red

PIGMENTO Red -

QUARTZ-ZINC

QUARTZ-ZINC -

Natural zinc

Natural zinc

Documents and drawings

Please enter your E-mail address. We will send you the download link by mail.

Installation

See all our installation videos-

It is important that all screws and clips used on an insulated metal panel must be flush to the surface of the panel within 2mm. For instances where this is not the case it is possible to use clips with a raised section that allows free thermal expansion and contraction of the zinc panel without any risk to the underside of the zinc.